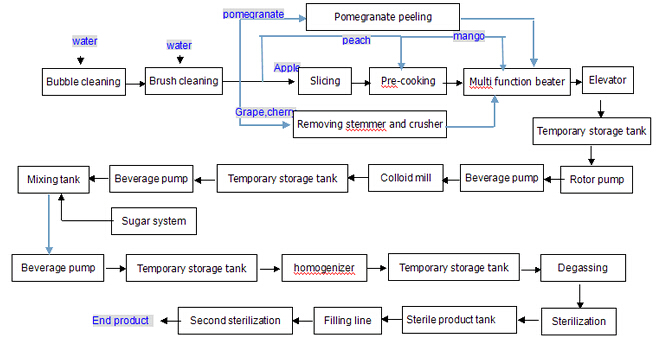

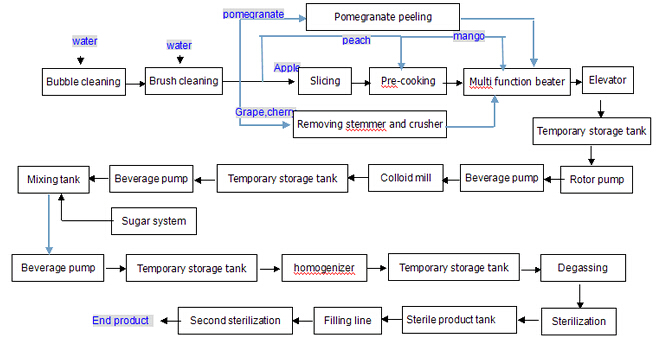

Three Phase Apple Juice Processing Equipment , Beverage Juice

Automatic Filling Machine

Production Line Performance

Raw materialFresh fruit:Mango, pineapple, orange, grape

Processing capacity800kg-1000kg/H

End productionFruit juice

Packing methodTo be confirmed

Packing volumeTo be confirmed

II. Supporting facilities

a. Re-circulating cooling water dosage: it is estimated to use the

5-8 tons of the cooling water depends on the actual processing

capacity

b. Source of the Re-circulating cooling water: running water

c. Water drainage facility: the workshop should be equipped with

enough floor drain device

d. Total power consumption: less than 800 KW

e. Power supply: three phase 380 V 50 HZ

f. It will need about 5-12 persons for the whole project, including

the packing.

g. Plant / factory area: about 600 square meter for the machine

workshop, the height: more than 5 meters.

Brush Washer Qty:1set

A. Power:0.75Kw 380V,50Hz;

B. Outline:2500×800×1000mm;

C. Working principle: this machine by artificial or ascend the

material, Material into the machine after the brush stick between

scrub, material use brush rotation, forward, spray pipe to material

of the dust of the world and dust to wash, if will brush the rod

hair silk diameter overstriking, can be the material the thorn

brushing, material of mud and thorn in under the action of water

pressure, the product tank discharge.

D. Materials:SUS304

Feed pump Qty:2set

A. Power:1.5Kw 380V,50Hz;

B. Outline:1600×420×370mm;

C. Working principle: when the motor to drive the pump rotation,

screw on the one hand around the axis of the rotating itself, on

the other hand it along the bushing inside

surface rolling, hence forming pump seal chamber, screw turn every

week, seal cavity of fluid forward a pitch, with screw continuous

rotation, liquid to spiral form from a seal cavity pressure to

another seal cavity, and finally extrusion pump body;

D. Material: the equipment and material contact part of the

material for SUS304 and four fluorine seals made of.

Syrup melting tank Qty:1set

A.Outline:¢1000×750mm;

B. Working principle: This machine is used for melting,

disinfecting, heating, heating, precooking, preparation, and

concentrating of the material in the food processing by steam, wine

production, pharmacy and daily chemical industry

De- Pulper Qty:1set

A. Power:15Kw 380V,50Hz;

B. Outline:1900×1400×1700mm;

C. Working principle: motor through the belt drive, make installed

in flower,The key

of rotor high-speed rotation, fruit by feed port into the machines,

feed the blades will

material screw conveyor to beating bar, in beating bar, under the

action of the material

being pound. Due to the existence of the centrifugal force, and the

material of the

juice and succulent (has become a slurry), through the screen on

the screen hole

into the next word beating (screen hole according to the fruit of

the size of the

nuclear and decide), nuclear the slag blade row to taphole, so as

to realize automatic

separation of slag slurry;

D. Materials:SUS304

Vacuum degasser Qty:1set

A. Power:2.2KW,380V,50HZ;

B. Outline:1200×850×1800mm

C. Working principle : vacuum degasser all and fruit and vegetable

juice contact parts for

high quality polished stainless steel materials and edible rubber,

TQ type is mainly

composed of machine body, head, nozzle, valve, apparent holes,

deflation, vacuum

pump, gas separator, etc.